|

THE 3DWAXMILLER CLUB.

A place to share your experiences with your 3dwaxmill system. 3D Wax Mill

|

| View previous topic :: View next topic |

| Author |

Message |

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sat Oct 25, 2008 7:02 pm Post subject: nice finish Posted: Sat Oct 25, 2008 7:02 pm Post subject: nice finish |

|

|

got a few jobs ....quite possibly my best finish yet!(with a brokin bit) no lines at all...one pass milling, final cut, on the mdx15

| Description: |

|

| Filesize: |

141.28 KB |

| Viewed: |

15220 Time(s) |

|

|

|

| Back to top |

|

|

jeff dunnington

Site Admin

Joined: 24 Feb 2004

Posts: 1586

Location: Houston, Tx

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sun Oct 26, 2008 11:01 am Post subject: Posted: Sun Oct 26, 2008 11:01 am Post subject: |

|

|

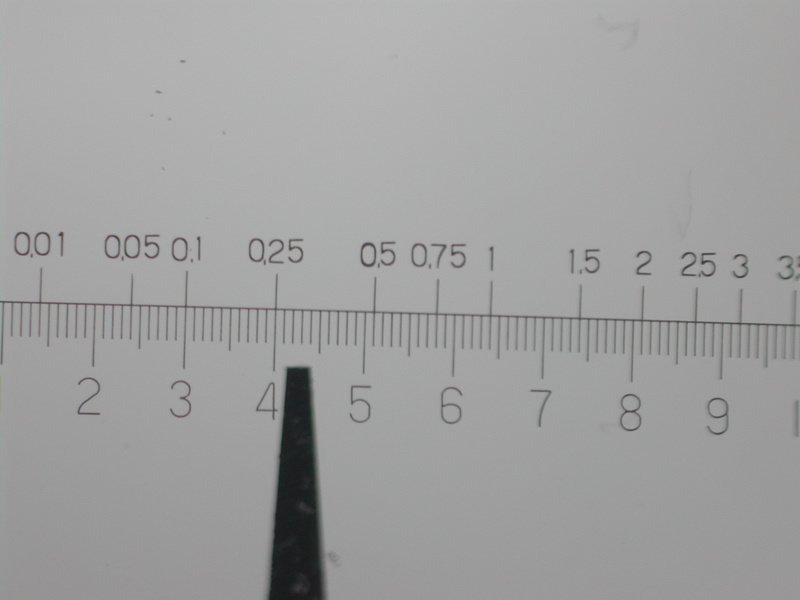

this bit started as a .005 ball end/taperd 10 deg bit... I ran it too fast (15,15) and broke the tip, wasn't to crazy about this bit untill it broke (left alot of packed swarf) however, I've noticed alot of the bits that break leave apx the same size tip .4mm so I use them for my 'general' cutting needs instead of throwing them away I find them to be a good overall working bit size.. there excellent for your full speed deep as well.. you can always go back in with a good bit if you feel it's necessary but 98% of the time it's not needed

I ran as a .3mm, 10 deg conical, x-y speed 10, z speed 15, .05 stepover one pass final cut I think it took about 15-20 min to mill I didn't look at the timer button or the clock..

here is a good loupe to have around to measure brokin bits with, you can get one at stuller, it has a measuring scale built in..I take my brokin bits and file the end flat with a fine diamond file then polish the end on a flat suface like a rouge stick

| Description: |

|

| Filesize: |

61.04 KB |

| Viewed: |

15213 Time(s) |

|

| Description: |

|

| Filesize: |

47.91 KB |

| Viewed: |

15213 Time(s) |

|

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Sun Nov 09, 2008 12:29 pm Post subject: Posted: Sun Nov 09, 2008 12:29 pm Post subject: |

|

|

been busy ...had to do a real job!! had to mill all of these, as the mold would not take, last minute rush....each one took 25min. ...done as a one pass final cut only, milled on a sheet all at once

charges

$200.00 design time

$80.00 each one

cast in silver

was that too low?

| Description: |

|

| Filesize: |

54.63 KB |

| Viewed: |

15170 Time(s) |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|