|

THE 3DWAXMILLER CLUB.

A place to share your experiences with your 3dwaxmill system. 3D Wax Mill

|

| View previous topic :: View next topic |

| Author |

Message |

Alfonso Vargas

Joined: 03 May 2011

Posts: 34

Location: San Antonio

|

Posted: Sun Feb 03, 2013 10:29 am Post subject: lonestar pendant Posted: Sun Feb 03, 2013 10:29 am Post subject: lonestar pendant |

|

|

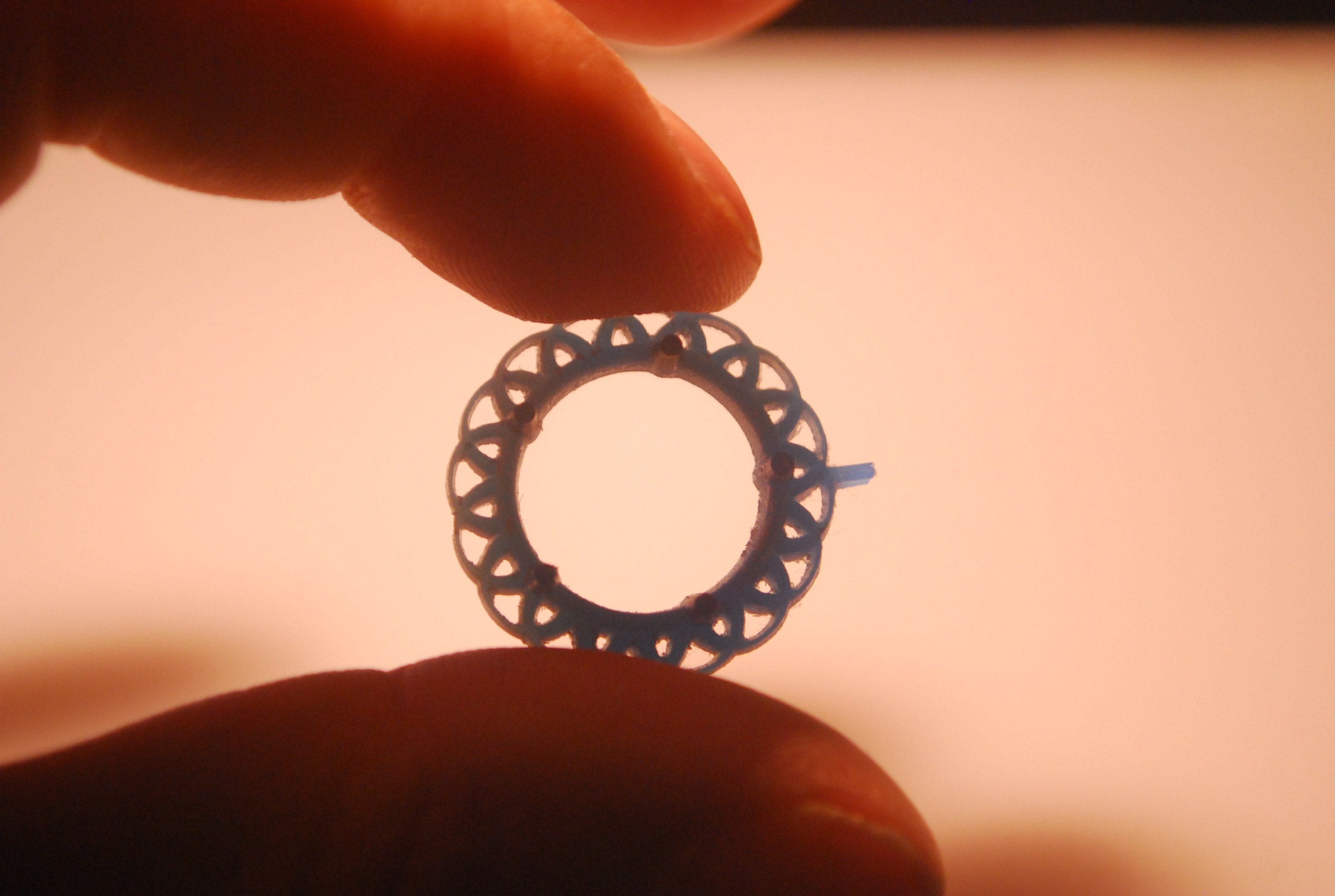

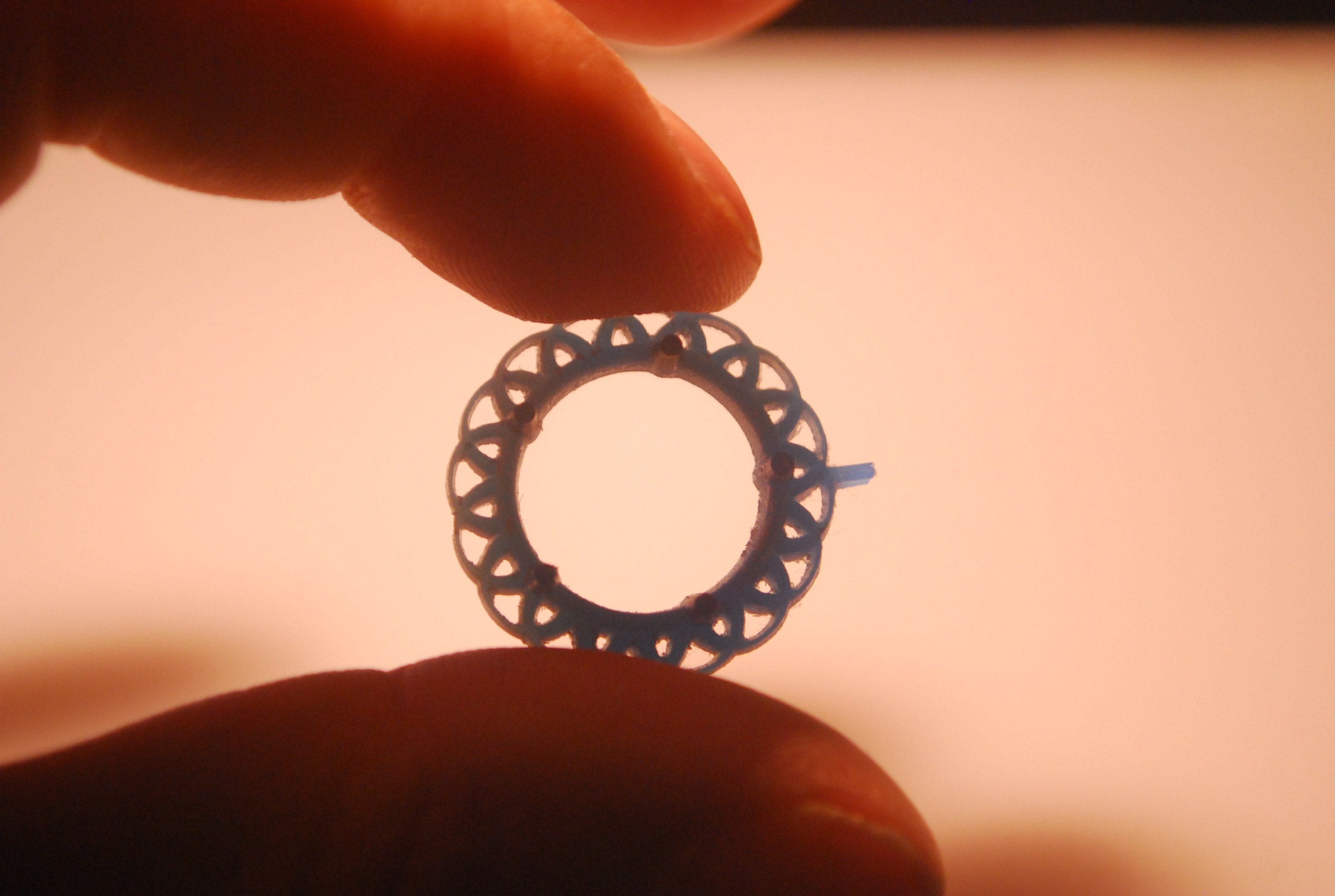

Hi guys wanted to show my wax for a lone star pendant this is the top. hand making the bottom. Im still having trouble with the bit sizes, I see you'all talking about .50 and so on Ive been using a 10 degree single pass cut. Need help on procedure of using bits

This was done on the MDX Thanks Jeff. was pretty eas,y now need to learn to do better on the flips.

| Description: |

|

| Filesize: |

136.15 KB |

| Viewed: |

13995 Time(s) |

|

| Description: |

|

| Filesize: |

483.23 KB |

| Viewed: |

13995 Time(s) |

|

|

|

| Back to top |

|

|

ToddMichael

Joined: 21 Jun 2008

Posts: 611

Location: Detroit, MI

|

Posted: Mon Feb 04, 2013 8:25 am Post subject: Posted: Mon Feb 04, 2013 8:25 am Post subject: |

|

|

Alfonzo;

Here is the post for tool set up, speed and parameters

[url]http://www.3dwaxmill.com/phpBB2/vt.php?t=1504

Also check out one pass milling and some of Pat Schmit's post on the filpper, and he plains the wax to the height and then mills in modela. There you can set up to mill past the bottom and get rid of the flanges I noticed in your casting.

Looks good, keep up with the jobs and the questions.

todd michael

[/url]

|

|

| Back to top |

|

|

p schmidt

Joined: 07 Apr 2004

Posts: 1314

Location: AURORA ,ILL. PHONE 630 552-9101

|

Posted: Mon Feb 04, 2013 9:14 am Post subject: Posted: Mon Feb 04, 2013 9:14 am Post subject: |

|

|

most all the time I use a 10 deg. 010 tapered ball end bit at full speed finish path (one pass cutting) ..If I'm cutting deeper then 5mm I'll slow it down a little maybe to 8-12 mps I don't worry about any other speed feed rates full throtle all the time is all you need with these bits they don't break.....anyway that's how I run my mill, may not be good for anyone else...

_________________

rhino4 and 5, rhino gold, hypershot, vector magic, next engine, cadwax ring builder, tsplines |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|